Описание

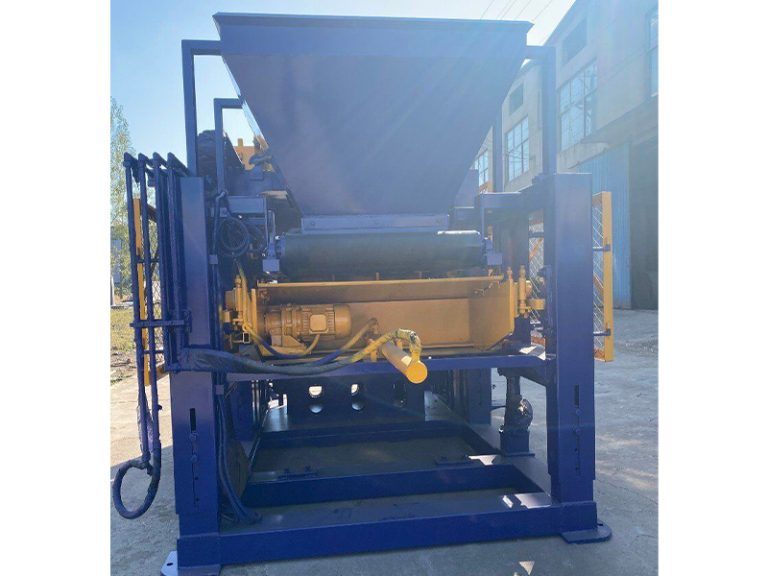

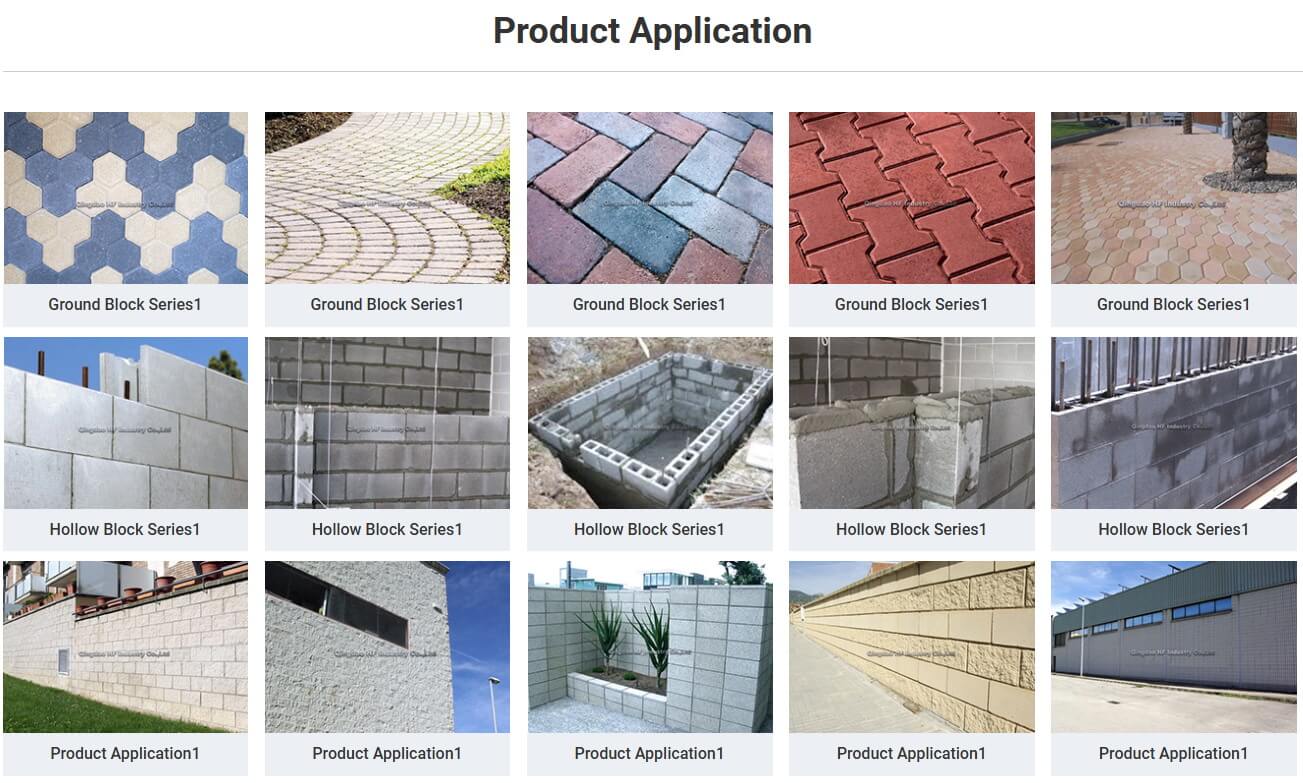

Полностью автоматическая машина для изготовления блоков QT6-15 — это наша популярная автоматическая машина для изготовления блоков, подходящая для изготовления пустотелых блоков, полнотелых кирпичей, тротуарной плитки, бордюрного камня и т. д. Эта машина автоматически управляется ПЛК, время цикла составляет 15–25 с, поэтому скорость производства очень высокая: для пустотелых блоков размером 8 дюймов она может производить более 11 520 шт. в день.

QT6-15 отличается от предыдущих моделей гидравлических блочных машин. Он имеет более широкий корпус и увеличивает производительность за счет увеличения размера формы. Мы приложили много усилий для улучшения синхронной и частотной силы вибрации гидравлической блочной машины.

Мы предоставляем полную техническую поддержку, включая планирование участка, руководство по установке, техническое обучение и послепродажное обслуживание.

Технические параметры

| Модель | QT4-15 | QT6-15 | QT8-15 | QT10-15 | QT12-15 |

| Сила воздужденияколебаний (KN) | 50 | 60 | 80 | 100 | 100 |

| Частота колебаний(HZ) | 0-50 | 0-60 | 0-60 | 0-60 | 0-60 |

| Мощность (KW) | 10.7 | 34.28 | 40.78 | 52.28 | 65.88 |

| Тип формования | Полуавтоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием |

| Управленный тип | полное автоматическое управление | полное автоматическое управление PLC | полное автоматическое управление PLC | полное автоматическое управление PLC | полное автоматическое управление PLC |

| Цикл формования (S) | 20-25 | 15-20 | 15-20 | 15-20 | 15-20 |

| Габаритный размер(mm) | 4388×1660×2100 | 7160×2000×2800 | 7500×2100×3020 | 7500×2500×3020 | 8200×2600×3020 |

| Вес машины (T) | 3 | 7 | 9 | 11 | 12 |

| Размер паллета | 840×500×20 | 880×680×20 | 860×860×20 | 1220×900×25 | 1400×950×30 |

Характеристики

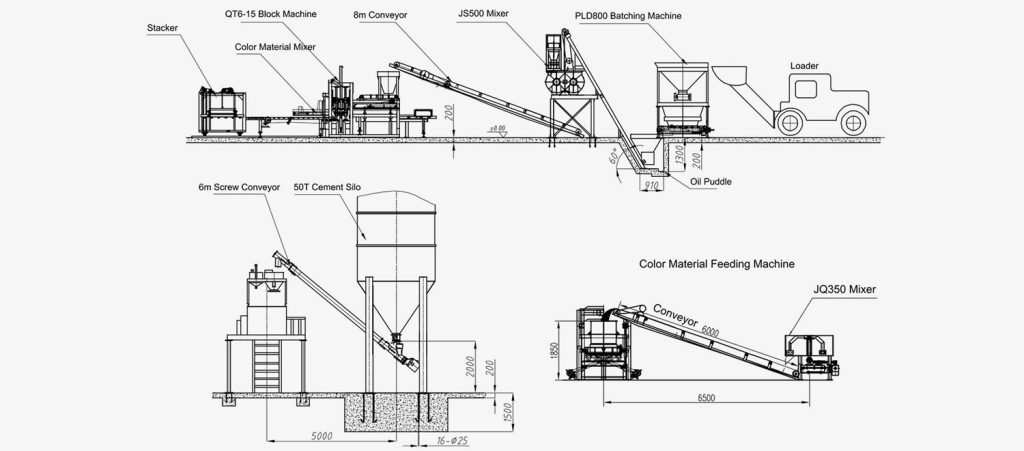

01.

Дозатор заполнителя

02.

Смеситель

03.

Весы цемента

04.

Винтовой конвейер

05.

Силос для цемента

06.

Ленточный конвейер

07.

Машина для производства бетонных блоков

08.

Гидравлическая станция

09.

Контрольный шкаф с компьютером PLC

10.

Автоматический блок-укладчик

Сила завода