Описание

Машины для изготовления блоков QT8-15 — это большие полностью автоматические машины для производства блоков. Они отлично подходят для профессиональных средних и крупных заводов по производству блоков. С помощью машин для производства блоков и вспомогательных машин можно производить все превосходные блоки и блоки по индивидуальному заказу. Машина для производства блоков производится из превосходного надежного сырья и имеет разумную структуру.

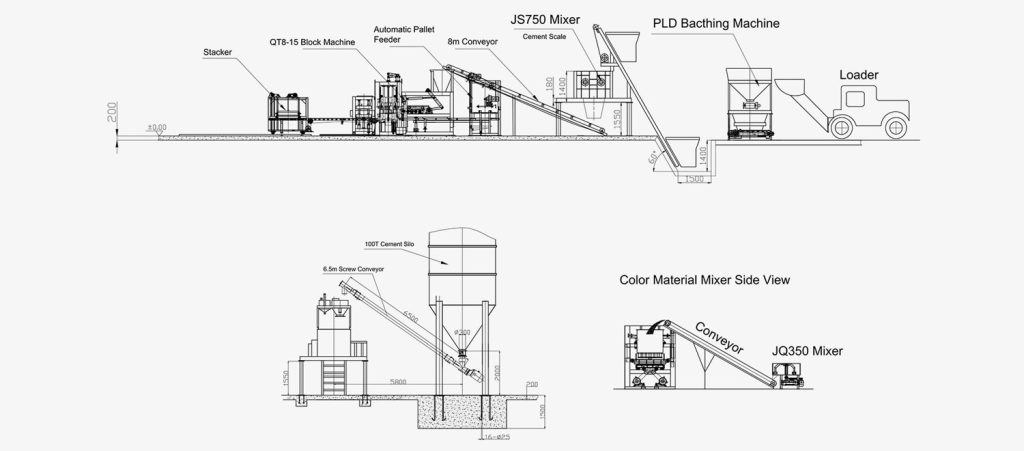

Машина для изготовления бетонных блоков QT8-15 — это полностью автоматическая гидравлическая машина для производства блоков, которая может быть объединена в автоматическую линию по производству блоков, оснащенную только дозирующим устройством, бетоносмесителем, цементным силосом, основной машиной для блоков, укладчиком блоков. Она управляется системой ПЛК, что позволяет экономить рабочую силу.

Технические параметры

| Модель | QT4-15 | QT6-15 | QT8-15 | QT10-15 | QT12-15 |

| Сила воздужденияколебаний (KN) | 50 | 60 | 80 | 100 | 100 |

| Частота колебаний(HZ) | 0-50 | 0-60 | 0-60 | 0-60 | 0-60 |

| Мощность (KW) | 10.7 | 34.28 | 40.78 | 52.28 | 65.88 |

| Тип формования | Полуавтоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием | автоматическо загрузка формование под вибропрессованием |

| Управленный тип | полное автоматическое управление | полное автоматическое управление PLC | полное автоматическое управление PLC | полное автоматическое управление PLC | полное автоматическое управление PLC |

| Цикл формования (S) | 20-25 | 15-20 | 15-20 | 15-20 | 15-20 |

| Габаритный размер(mm) | 4388×1660×2100 | 7160×2000×2800 | 7500×2100×3020 | 7500×2500×3020 | 8200×2600×3020 |

| Вес машины (T) | 3 | 7 | 9 | 11 | 12 |

| Размер паллета | 840×500×20 | 880×680×20 | 860×860×20 | 1220×900×25 | 1400×950×30 |

| Тип блока | Фото | Размер (мм) Д*Ш*В | Цикл формования | Кол-во(шт.)/Форма | Кол-во(шт)/час | Кол-во(шт)/8ч |

| Пустотелый блок | 400x200x200 | 15-20 | 8 | 1440-1920 | 11520-15360 | |

| Пустотелый блок | 400x150x200 | 15-20 | 12 | 2160-2880 | 17280-23040 | |

| Твердый блок | 240x110x70 | 15-17 | 33 | 6988-7920 | 55904-63360 | |

| Тротуарный блок | 225×112.5×60 | 15-25 | 21 | 3000-3780 | 24000-30240 | |

| Тротуарный блок | 200x100x60 | 15-25 | 32 | 4600-7680 | 36800-61440 |

Автоматическая машина для производства блоков

01.

Серье :промышленные отходы как щебень,песок,цемент,уголная золь,пыль,гарьшлак,угольные отходы,галяперлит и т.д.

02.

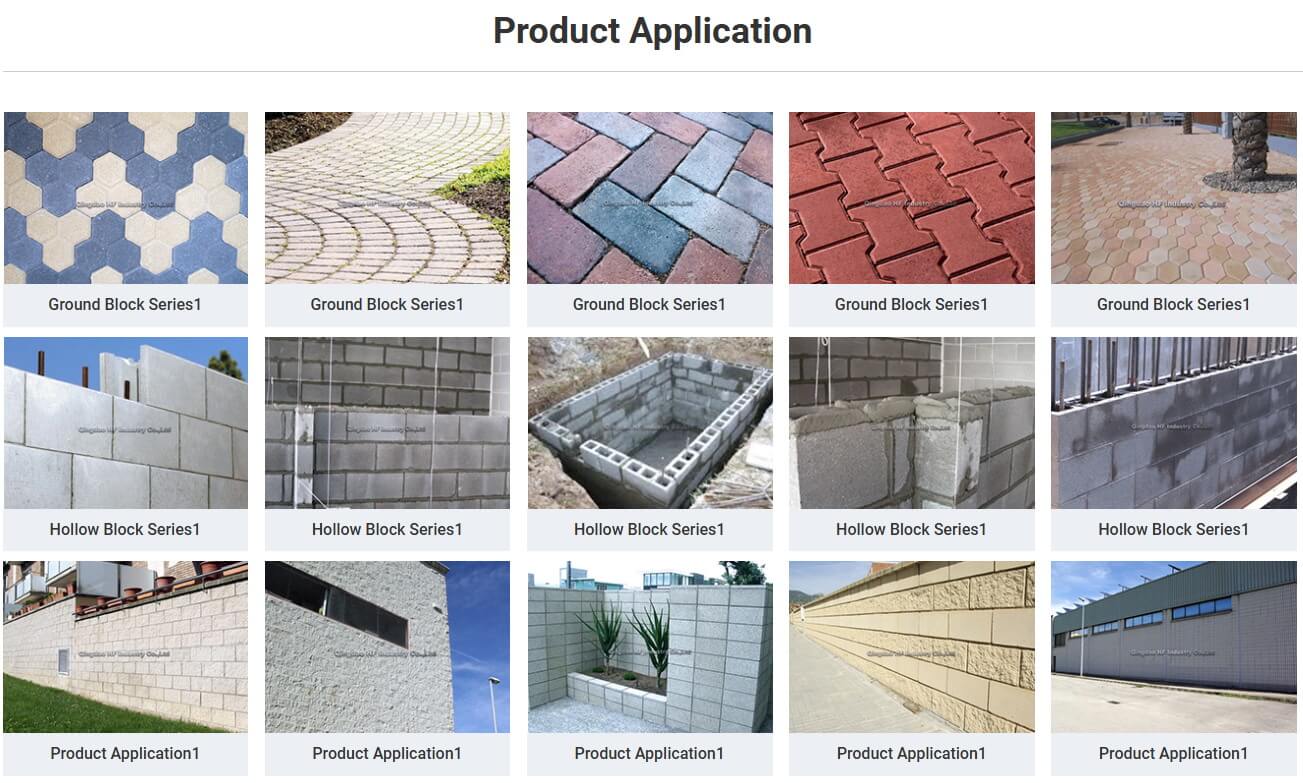

Применение на продукт:бетонный стеновой строительный блоксплошной\полый\пористая блок изделия, булыжник для садового пейзажа, кирпич камень и т.д.

03.

Применение: Широко используется в строительстве, дорожном покрытии, парковых зонах, озеленении, городском развитии и т. д.

Характеристики

- Дозатор заполнителя

- Смеситель

- Весы цемента

- Винтовой конвейер

- Силос для цемента

- Ленточный конвейер

- Машина для производства бетонных блоков

- Гидравлическая станция

- Контрольный шкаф с компьютером PLC

- Автоматический блок-укладчик

Сила завода